商铺名称:山东科锐尔激光设备有限公司

联系人:聂鑫坡()

联系手机:

固定电话:

企业邮箱:coral_market@163.com

联系地址:曲阜市书院工业园圣旺大道南首路西

邮编:

联系我时,请说是在快能纺机网上看到的,谢谢!

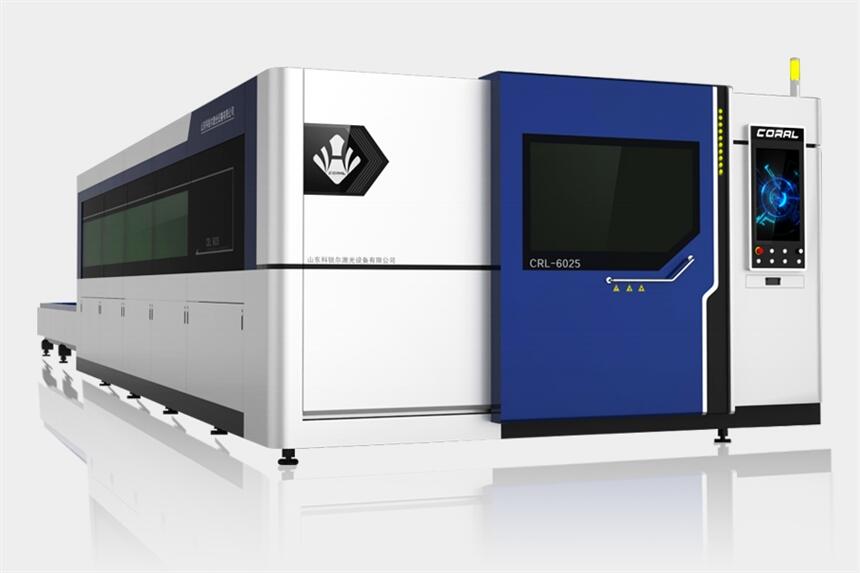

山东科锐尔激光设备有限公司

Shandong Coral Laser Equipment Co.,Ltd

山东科锐尔激光设备有限公司注册成立于2019年4月29日,占地面积20000平方米。公司以发扬工匠精神,打造高端装备为目标,拥有一批知识化、年轻化的技术队伍致力于高品质激光切割机、激光焊接机、激光打标机以及其他激光设备的研发,生产及销售。目前我司激光切割机现有机型包括CRL-3015,CRL-4020,CRL6025,交换平台和板管一体机以及10025单台机和客户定制的其他机型,激光器功率从1000瓦到15000瓦。同时我们也在努力研发更高功率的激光切割机。

Shandong Coral Laser Equipment Co.,Ltd was registered on April 29th,2019, covers a total area of20000 square meters. We aim for carrying forward craftsman's spirit and building high-end equipment, with a group of knowledgeable, young technical team committed to high-quality laser cutting machine, laser welding machine, laser marking machine and other laser equipment research and development, production and sales. Our current laser cutting machine include CRL-3015,CRL-4020,CRL6025 single platform, exchange platform and plat-tube integrated machine, and CRL-10025 single platform . Laser power range from 1000W to 12000W, meanwhile we are trying to research for the higher power laser cutting machine.

激光切割机简介

激光切割机技术采用激光束照射到金属板材表面时释放的超高能量,使金属板材倍照射处瞬间熔化或气化并由辅助气体将熔渣吹走,再通过数控机械系统移动光斑照射维智而实现自动切割,它是集最先进的光纤激光技术,数控技术,精密机械技术于一体的高技术设备。

Fiber laser cutting machine uses the most advanced imported fiber laser to output the laser beam with high energy density and focus on the working surface to make the area of the workpiece wher irradiated by an ultrafine focus light spot instantly melted and gasified, by moving the irradiation location through the numberical control system to realize the automatic cutting, is is a high-tech equipment that integrates the most advanced fiber laser technology, numberical control and precision equipment.

激光切割机的主要用途 Fiber Laser Cutting Machine main application

主要用于碳钢、硅钢、不锈钢、铝合金、钛合金、镀锌板等多种金属材料快速切割。

Mainly cutting carbon steel, silicon steel , stainless steel, aluminum alloy, titanium alloy, galvanized steel and other metal material.

广泛应用于钣金、五金制品、钢结构、精密机械、汽车配件、铭牌、广告、工艺品等行业。Widely used on metal plate, hardware, steel structure, precision machinery, auto spare parts, advertise, areware and etc.

产品介绍 Production introduce

单平台光纤激光切割机

Single platform Fiber Laser Cutting Machine

光纤激光切割机特点:

1. 优秀的光束质量:聚焦光斑更小,切割线条更精细,工作效率更高,加工质量更好;

2. 极高的切割速度:是同等功率CO2激光切割机的2倍;

3. 极高的稳定性:光纤激光器,性能稳定,关键部件使用寿命可达10 万小时;

4. 极高的电光转换效率:光纤激光切割机比CO2激光切割机电光转换效率高3倍;

5. 极低的使用成本:整机耗电量仅为同类CO2激光切割机的20-30%;

6. 极低的维护成本:无激光器工作气体;光纤传输,无需反射镜片;可节约大量维护成本;

7. 产品操作维护方便:光纤传输,无需调整光路;

8. 超强的柔性导光效果:体积小巧,结构紧凑,易于柔性加工要求。

Fiber Laser Cutting Machine Main Features:

1. Superior beam quality: smaller focusing spot, finer cutting lines, higher efficiency and better machining quality.

2. Very high cutting speed: 2 times of the same power CO2 laser cutting machine

3. Extremely high stability: fiber laser, stable performance, the service life of key components up to 100,000 hours.

4. Extremely high electro-optical conversion efficiency: optical fiber laser cutting machine is 3 times more efficient than CO2 laser cutting machine.

5. Extremely low operating cost: the power consumption of the whole machine is only 20-30% of the same kind of CO2 laser cutting machine.

6. Very low maintenance cost: no laser working gas;Optical fiber transmission, no reflective lenses;Can save a lot of maintenance cost.

7. Easy operation and maintenance: optical fiber transmission, no need to adjust the optical path.

8. Super flexible light guiding effect: small size, compact structure, easy to flexible processing requirements.

产品特性:

采用高强度整体板材焊接机身,经过高温退火,机床正常使用20年不变形。以进口精密齿轮齿条、直线导轨、传动运行,从而实现了机床的高精密、高效率、高稳定性。该设备采用激光专用速配系统,高性能伺服电机驱动,缩短待机时间,有效提高工作效率30%以上。

This machine is welded with a high-intensity overall sheet, and after high temperature annealing, the machine can be used for 20 years without any deformation. With imported precision gear and rack, linear guide rail and transmission, the machine tool is of high precision, high efficiency and high stability. The equipment adopts the laser special matching system, high performance servo motor drive, this shorten the standby time and improve the work efficiency more than 30%, is the integration fo pneumatic, mechanical, photoelectric, numerical control and other advanced technologies as one of the high-tech products.

|

CRL-3015A |

CRL-4020A |

CRL-6025A |

CRL-10025A |

CRL-14025A |

|

|

切割范围 Cutting Range |

3000*1500mm |

4000*2000mm |

6000*2500mm |

10000*2500mm |

14000*2500mm |

|

激光器类型 Laser model |

光纤激光器 Fiber Laser generator |

||||

|

激光功率 Laser Power |

1000W/1500W/2000W/3000W |

1000W/1500W/2000W/3000W |

1500W/2000W/3000W/6000W/8000W |

3000W/6000W/8000W/12000W |

3000W/6000W/8000W/12000W/15000W |

|

空行速度 Max moving speed |

100m/min |

100m/min~120m/min |

100m/min~120m/min |

100m/min~120m/min |

100m/min~140m/min |

|

切割速度 Max cutting speed |

35~80m/min |

35~80m/min |

35~100m/min |

35~100m/min |

35~120m/min |

|

定位精度 Positioning accuracy |

0.03mm |

0.03mm |

0.03mm |

0.03mm |

0.03mm |

|

重复定位精度 Reposition accuracy |

0.02mm |

0.02mm |

0.02mm |

0.02mm |

0.02mm |

|

最小线宽 Min line width |

0.1mm |

0.1mm |

0.1mm |

0.1mm |

0.1mm |

|

电源需求 Power supply |

三相380V/50HZ/60HZ |

||||

封闭式交换平台激光切割机

Closed Type exchange platform fiber laser cutting machine

封闭式交换平台光纤激光切割机的特点

1. 封闭式加工环境,防尘、防烟、安全环保。

2. 整体重型龙门结构机床、高强度焊接钢滑梁,整体刚性好,性能稳定。

3. 进口高精度传动装置与伺服系统完美匹配,保证切割精度与效率

4. 专业激光切割数控系统,自动寻边、自动排料、提高板材利用率和生产效率。

5. 高速交换工作台,简化工作流程节约时间。

Closed type exchange platform fiber laser cutting machine main features:

1. Closed processing environment, dustproof, smoke proof, safe and environmental protection.

2. Entriely heavy gantry structure machine tool, high strength welded steel beam, good rigidity, stable performance.

3. Imported high-precision transmission device, perfectly matched with servo system to ensure cutting accuracy and efficiency.

4.Professional laser cutting CNC system, automatic edge finding, automatic material arrangement, improve the utilization rate of plate and production efficiency.

5.High speed exchange platform, make the work flow simply and save time.

5.High speed exchange platform, make the work flow simply and save time.

|

型号Model |

CRL-3015B |

CRL-4020B |

CRL-6025B |

|

切割范围 Cutting Range |

3000*1500mm |

4000*2000mm |

6000*2500mm |

|

激光功率 Laser Power |

1000W/1500W/2000W |

1000W/1500W/2000W |

1500W/2000W/3000W/6000W |

|

空行速度 Max moving speed |

100m/min |

120m/min |

120m/min |

|

切割速度 Max cutting speed |

35~100m/min |

35~100m/min |

35~100m/min |

|

定位精度 Positioning accuracy |

0.03mm |

0.03mm |

0.03mm |

|

重复定位精度 Reposition accuracy |

0.02mm |

0.02mm |

0.02mm |

|

最小线宽 Min line width |

0.1mm |

0.1mm |

0.1mm |

激光切管机 Tube Laser Cutting machine.

数字化全行程卡盘,无需人工调节;Digital chuck without manual adjustment.

智能压力反馈系统. Intelligent pressure feedback system.

切割材料:专业切割方管,圆管,矩形管等各类型管材

Cutting material: Professional cut square tube, round tube, rectangle tube and etc.

方管:12*12mm~200*200mm, 圆管: ?12~254mm,

Square tube: 12*12mm~200*200mm, round tube:?12~254mm,

管壁厚度0.5mm~10mm碳钢管,不锈钢管。(厚度以及材料与激光器有关)。

Tube wall thickness: 0.5mm~10mm, carbon steel tube, stainess steel tube.(Wall thickness and material is related with laser machine)

|

加工管径 Process tube diameter |

激光器功率 Laser machine power |

运行速度Maximum running speed |

加速度 Maximum acceleration |

|

?12~219mm*6000mm |

1000W~6000W |

120m/min |

1.2G |

|

定位精度 Positional accuracy |

重复定位精度 Reprated positioning accuracy |

整机重量 Total weight |

外观尺寸 External dimension |

|

±0.03mm/m |

±0.03mm |

12000kg |

12000*3500*2800mm |

|

激光器功率 Laser power |

1000W~12000W(可选/Optical) |

|

卡盘夹持直径范围 Effective cutting diameter |

?12~219mm |

|

管材加工长度 Effective cutting length |

6000mm |

|

定位精度 Positional accuracy |

±0.03mm |

|

重复定位精度 Repeat positional accuracy |

±0.03mm |

|

加速度 Maximum acceleration |

1.2G |

|

电源需求 Power supply |

三相 380V/50HZ/60HZ |

板管一体激光切割机 Plate and tube integrated laser cutting machine.

该机型采用伺服电机驱动,齿轮齿条传动,高精度卡盘配合高精度伺服减速系统,推进式切管的方式,并配备专用的柏楚切管软件,夹持范围可达15—220mm圆管,可用于一般的钣金切割及常见的方管、圆管、矩形管的切割。This machine adopts servo motor drive, rack and pinion drive, high precision chuck with high precision servo deceleration system, propulsive pipe cutting way, and match professional FS cut sofeware, the maximum clamping range from 15mm to 220mm round tube. It can be used for commen metal plate cutting and rectangle pipe, round pipe, and square pipe cutting.

主要功能:Main function

1、能在主管上切割多个不同方向、不同直径的圆柱相贯线孔,满足支管轴线与主管轴线偏心和非偏心的垂直相交的条件。

2、能在支管端部切割圆柱相贯线端头,满足支管轴线与主管轴线偏心和非偏心的垂直相交、倾斜相交的条件。

3、能在圆管端部切割斜截端面。

4、能在圆管上切割焊接弯头,“虾米节”两端斜截断面。

5、能切割与环形主管相交的支管相贯线端头。

6、能切割变角度坡口面。

7、能在圆管上切割方孔、腰形孔。

8、能进行钢管截断。

9、能在方管上切割各种图形。

Main function

1. It can cut a number of cylindrical intersecting line holes in different directions and diameters on the main pipe to meet the condition that the branch pipe axis intersects with the main pipe axis in a vertical way that is eccentric or non-eccentric.

2. It can cut the end of the cylindrical intersecting line at the end of the branch pipe to meet the conditions of vertical and oblique intersection between the branch pipe axis and the main pipe axis, eccentric and non-eccentric.

3. Can cut slope-intercept face at the end of the pipe.

4. Can cut and weld elbows on the round pipe, and cut oblique surfaces at both ends.

5. It can cut the end of the intersecting line of the branch pipe intersecting with the ring main pipe.

6. Can cut the bevel surface with varying angles.

7. Can cut square hole and waist hole on round pipe.

8. Steel pipe can be cut off

9. Can cut all kinds of graphics on square pipe

|

设备型号 Equipment type |

CRL-3015C |

CRL-4020C |

CRL-6025C |

|

激光波长 Laser wavelength |

1064nm |

1064nm |

1064nm |

|

脉冲频率 Impulse frequency |

1--300HZ |

1--300HZ |

1--300HZ |

|

最小线宽 Minimum linewidth |

0.15mm |

0.15mm |

0.15mm |

|

· 板材加工幅面 Board process Area |

3000mm×1500mm |

4000mm×1500mm |

6000mm×1500mm |

|

切割板材厚度 Board thickness |

0.2㎜-15mm |

0.2㎜-20mm |

0.2㎜-25mm |

|

管材切割直径 Tube diameter |

10-220mm |

10-220mm |

10-220mm |

|

管材切割长度Tube length |

6000mm |

6000mm |

6000mm |

|

切割管壁厚度 Pipe wall thickness |

0.2-5mm |

0.2-5mm |

0.2-5mm |

|

电力配置 Power |

380V/50HZ/100A |

380V/50HZ/100A |

380V/50HZ/100A |

|

X、Y、Z轴几何定位精度 · X, Y, Z axis geometric positioning accuracy ·

|

≤±0.08㎜/1000㎜ |

≤±0.08㎜/1000㎜ |

≤±0.08㎜/1000㎜ |

|

X、Y、Z轴重复定位精度Repeat positioning accuracy |

≤±0.04㎜ |

≤±0.04㎜ |

≤±0.04㎜ |

|

冷却方式 Cooling method |

水冷 |

水冷 |

水冷 |

|

切割速度 Cutting speed |

35㎜/s |

35㎜/s |

35㎜/s |