商铺名称:上海夕彩印刷设备有限公司

联系人:宋女士()

联系手机:

固定电话:

企业邮箱:2029812815@qq.com

联系地址:上海上海宝山区上海市宝山区淞南通南路333号2号楼1楼115室

邮编:

联系我时,请说是在快能纺机网上看到的,谢谢!

商品详情

加工定制是

货号390a

型号390a

覆膜宽度370mm

覆膜速度0-10米/分钟

电热功率1.6kw

覆膜温度80-125℃

适用纸张不限制

机重220t

外型尺寸0.9*0.63*1.2mm

品牌夕彩

电机功率1.6kw

包装木箱

类型自动覆膜机

进纸方式自动

自动切断手动

加热方式油加温

展开

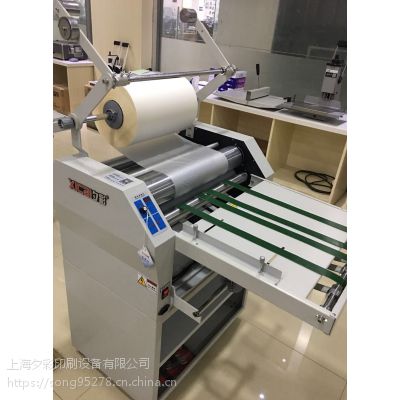

湖南夕彩 油加温覆膜机390a

点我去除广告

湖南夕彩 油加温覆膜机390a 不褶皱速度快捷

上海夕彩 油加温覆膜机fm390a

技术参数:

宽度:370mm

覆膜速度:0-10m/min

覆膜温度:80-125摄氏度

芯片规格:一寸/三寸芯

进纸方式:自动

自动切断:手动

修边点线刀:有

自动收卷:有

防卷功能:有

加热:油加温

电源参数:220v 50hz 1.6kw

总功率:1.6kw

尺寸:0.9*0.63*1.2

净重:220kgs

oil-heated film covering machine fm390a

technical parameters:

width: 370 mm

covering speed: 0-10m / min

covered temperature: 80-125 degrees celsius

chip specs: 1 inch / 3 inch core

paper feed: automatic

automatic cut: manual

repair edge line knife: yes

automatic roll collection: yes

anti-roll function: yes

heating: oil heating

power parameters: 220v50hz 1.6 kw

total power: 1.6 kw

size: 0.9 * 0.63 * 1.2

net weight: 220 kgs

a设备

1、开关

2、操作页面说明,温度显示屏,单面覆膜开关 ,温度关,双面覆膜开光,反转,停止,正转,速度调节钮

3、刀架 ,拉拢刀片,操作页面可移动进纸挡板,电源开关

4、输送带,操作页面,放膜轴,防卷调节杆,出纸压力杆 ,主压力杆

a equipment

1, switch

2, operation page description, temperature display, single-sided film switch, temperature off, double-sided film open light, reverse, stop, positive turn, speed adjustment button

3, knife frame, draw blades, operating pages can be moved into the paper baffle, power switch

4, conveyor belt, operation page, film shaft, anti-roll adjustment bar, paper pressure bar, main pressure bar

油加温覆膜机390a

先接通电源

1加温。开机前。开启机器辊筒加热,使辊筒温度爿高到覆膜要求 ( 一般为 50 -65 ℃ )

使胶液循环均匀。 2 启动胶泵。开启胶泵开关。

3上膜。上膜时一定要把塑料薄膜的处理面和胶辊接触。

4敲纸。将纸边经翻转敲压成等距离且呈扇形的挺而硬的折痕。

5配制黏合剂。

6调节上胶辊与涂胶辊间的工作间隙。 以保证润滑良好。

7打开烘道、收料、排风的开关。同时可把应添加机油、黄油的部位按规定要求加注机油、黄油。

8检查纸张输送带前方小胶辊的间隙是否一致。

9打压力、送膜、切边。 两手根据印刷品的幅面,

10调规矩。松开规矩固定螺钉。同时向前推或向后推,保证纸张在输送带上的运行方向与热压辊筒保持垂直,平稳地进入复合热压机构,同时还要使塑料薄膜合适地压在印刷品上,既不虚膜又不跑边。

温度是否符合工艺要求,

11检查机器。检查机器各部位运转是否正常。开关是否全开。一切正常后,才能进行压胶。

迫使薄膜平稳地与涂胶辊接触,

12压胶。压胶是旋动压力装置。以保证胶液均匀连续地涂布在塑料薄膜上。

13收卷,检查复合质量。

connect the power first.

1 heated. before the boot. turn on the machine roller to heat up the temperature of the roller to the film cover requirements(usually 50-65 °c)

make the glue cycle even. 2 activate rubber pump. turn on the rubber pump switch.

3 upper membrane. be sure to put the plastic film treatment surface and roller contact.

4 knocking paper. the edge of the paper is flipped and pressed into a straight and hard crease with an equal distance and a fan shape.

5 preparation of adhesives.

6 adjust the working gap between the rubber roller and the rubber roller. to ensure good lubrication.

7 turn on the oven, the material, and the wind. at the same time, the parts that should be added oil and butter can be added to the oil and butter as required by the regulations.

8 check the paper conveyor belt in front of the small roll clearance is consistent.

9 hit pressure, film, cutting edge. two hands on the width of the print,

10 rules. loosen the rules and fix the screws. at the same time, push forward or push backwards to ensure that the running direction of the paper on the conveyor belt is perpendicular to the hot pressure roller and enters the composite hot pressure mechanism smoothly. at the same time, the plastic film must be properly pressed on the printed matter. it is neither virtual film nor running edge.

whether the temperature meets the process requirements,

check the machine. check that all parts of the machine are functioning properly. whether the switch is on or not. after everything is normal, you can do the pressing glue.

to force the film into steady contact with the coated roller,

12 pressure glue. pressure rubber is a rotating pressure device. to ensure that the glue is evenly and continuously coated on the plastic film.

13 volume, check compound quality.

主要部件说明

图一

图二

图三

注意事项与保养

1、滚筒表面要保持干净,如发现表面擦洗不掉导致产品美观度受损要拆卸滚筒修磨,在操作过程中,有薄膜粘粘时停机,待滚筒清洗干净后再开机操作。清洗滚筒时务必小心,防止清洁布或手挤压进去,造成对人身不安和滚筒损坏。

2、本机不工作时,辊与辊之间要相互脱离,使橡胶辊处于松弛状态,以免摩擦胶辊处于松弛状态,以免橡胶辊受到变形损坏。

3、各部件连接螺栓要经常检查,机身必须接地,以防触电。

notes and maintenance

1, the surface of the drum must be kept clean, if the surface scrub can not be removed resulting in damage to the beauty of the product to remove the drum repair grinding, in the operation process, there is a film sticking stop, wait until the drum clean operation. when cleaning the drum must be careful to prevent the clean cloth or hand squeeze into, causing personal uneasiness and drum damage.

when the machine is not working, the roll and the roll must be separated from each other, so that the rubber roll is in a relaxed state, so as not to make the friction roller in a relaxed state, so as not to prevent the rubber roll from being deformed and damaged.

the connecting bolts of each part should be checked frequently, and the fuselage must be grounded to prevent electric shock.

货号390a

型号390a

覆膜宽度370mm

覆膜速度0-10米/分钟

电热功率1.6kw

覆膜温度80-125℃

适用纸张不限制

机重220t

外型尺寸0.9*0.63*1.2mm

品牌夕彩

电机功率1.6kw

包装木箱

类型自动覆膜机

进纸方式自动

自动切断手动

加热方式油加温

展开

湖南夕彩 油加温覆膜机390a

点我去除广告

湖南夕彩 油加温覆膜机390a 不褶皱速度快捷

上海夕彩 油加温覆膜机fm390a

技术参数:

宽度:370mm

覆膜速度:0-10m/min

覆膜温度:80-125摄氏度

芯片规格:一寸/三寸芯

进纸方式:自动

自动切断:手动

修边点线刀:有

自动收卷:有

防卷功能:有

加热:油加温

电源参数:220v 50hz 1.6kw

总功率:1.6kw

尺寸:0.9*0.63*1.2

净重:220kgs

oil-heated film covering machine fm390a

technical parameters:

width: 370 mm

covering speed: 0-10m / min

covered temperature: 80-125 degrees celsius

chip specs: 1 inch / 3 inch core

paper feed: automatic

automatic cut: manual

repair edge line knife: yes

automatic roll collection: yes

anti-roll function: yes

heating: oil heating

power parameters: 220v50hz 1.6 kw

total power: 1.6 kw

size: 0.9 * 0.63 * 1.2

net weight: 220 kgs

a设备

1、开关

2、操作页面说明,温度显示屏,单面覆膜开关 ,温度关,双面覆膜开光,反转,停止,正转,速度调节钮

3、刀架 ,拉拢刀片,操作页面可移动进纸挡板,电源开关

4、输送带,操作页面,放膜轴,防卷调节杆,出纸压力杆 ,主压力杆

a equipment

1, switch

2, operation page description, temperature display, single-sided film switch, temperature off, double-sided film open light, reverse, stop, positive turn, speed adjustment button

3, knife frame, draw blades, operating pages can be moved into the paper baffle, power switch

4, conveyor belt, operation page, film shaft, anti-roll adjustment bar, paper pressure bar, main pressure bar

油加温覆膜机390a

先接通电源

1加温。开机前。开启机器辊筒加热,使辊筒温度爿高到覆膜要求 ( 一般为 50 -65 ℃ )

使胶液循环均匀。 2 启动胶泵。开启胶泵开关。

3上膜。上膜时一定要把塑料薄膜的处理面和胶辊接触。

4敲纸。将纸边经翻转敲压成等距离且呈扇形的挺而硬的折痕。

5配制黏合剂。

6调节上胶辊与涂胶辊间的工作间隙。 以保证润滑良好。

7打开烘道、收料、排风的开关。同时可把应添加机油、黄油的部位按规定要求加注机油、黄油。

8检查纸张输送带前方小胶辊的间隙是否一致。

9打压力、送膜、切边。 两手根据印刷品的幅面,

10调规矩。松开规矩固定螺钉。同时向前推或向后推,保证纸张在输送带上的运行方向与热压辊筒保持垂直,平稳地进入复合热压机构,同时还要使塑料薄膜合适地压在印刷品上,既不虚膜又不跑边。

温度是否符合工艺要求,

11检查机器。检查机器各部位运转是否正常。开关是否全开。一切正常后,才能进行压胶。

迫使薄膜平稳地与涂胶辊接触,

12压胶。压胶是旋动压力装置。以保证胶液均匀连续地涂布在塑料薄膜上。

13收卷,检查复合质量。

connect the power first.

1 heated. before the boot. turn on the machine roller to heat up the temperature of the roller to the film cover requirements(usually 50-65 °c)

make the glue cycle even. 2 activate rubber pump. turn on the rubber pump switch.

3 upper membrane. be sure to put the plastic film treatment surface and roller contact.

4 knocking paper. the edge of the paper is flipped and pressed into a straight and hard crease with an equal distance and a fan shape.

5 preparation of adhesives.

6 adjust the working gap between the rubber roller and the rubber roller. to ensure good lubrication.

7 turn on the oven, the material, and the wind. at the same time, the parts that should be added oil and butter can be added to the oil and butter as required by the regulations.

8 check the paper conveyor belt in front of the small roll clearance is consistent.

9 hit pressure, film, cutting edge. two hands on the width of the print,

10 rules. loosen the rules and fix the screws. at the same time, push forward or push backwards to ensure that the running direction of the paper on the conveyor belt is perpendicular to the hot pressure roller and enters the composite hot pressure mechanism smoothly. at the same time, the plastic film must be properly pressed on the printed matter. it is neither virtual film nor running edge.

whether the temperature meets the process requirements,

check the machine. check that all parts of the machine are functioning properly. whether the switch is on or not. after everything is normal, you can do the pressing glue.

to force the film into steady contact with the coated roller,

12 pressure glue. pressure rubber is a rotating pressure device. to ensure that the glue is evenly and continuously coated on the plastic film.

13 volume, check compound quality.

主要部件说明

图一

图二

图三

注意事项与保养

1、滚筒表面要保持干净,如发现表面擦洗不掉导致产品美观度受损要拆卸滚筒修磨,在操作过程中,有薄膜粘粘时停机,待滚筒清洗干净后再开机操作。清洗滚筒时务必小心,防止清洁布或手挤压进去,造成对人身不安和滚筒损坏。

2、本机不工作时,辊与辊之间要相互脱离,使橡胶辊处于松弛状态,以免摩擦胶辊处于松弛状态,以免橡胶辊受到变形损坏。

3、各部件连接螺栓要经常检查,机身必须接地,以防触电。

notes and maintenance

1, the surface of the drum must be kept clean, if the surface scrub can not be removed resulting in damage to the beauty of the product to remove the drum repair grinding, in the operation process, there is a film sticking stop, wait until the drum clean operation. when cleaning the drum must be careful to prevent the clean cloth or hand squeeze into, causing personal uneasiness and drum damage.

when the machine is not working, the roll and the roll must be separated from each other, so that the rubber roll is in a relaxed state, so as not to make the friction roller in a relaxed state, so as not to prevent the rubber roll from being deformed and damaged.

the connecting bolts of each part should be checked frequently, and the fuselage must be grounded to prevent electric shock.

在线询盘/留言