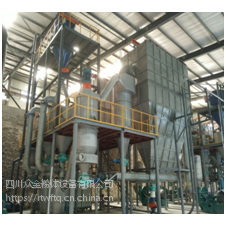

分级式冲击磨硬质高岭土、滑石、石墨、方解石、石膏、硅藻土、硅灰石、重晶石、叶腊石、氢氧化铝粉碎

产品价格:¥(人民币)

商铺名称:苏州市上宇纺机配件厂

联系人:周先生()

联系手机:

固定电话:

企业邮箱:

联系地址:江苏苏州江苏苏州市浒关镇浒关北路商苑路88号

邮编:

联系我时,请说是在快能纺机网上看到的,谢谢!

商品详情

品牌众金

适用物料通用

进料粒度≤3mm

出料粒度0.075mm

原理高速万能粉碎机

展开

分级式冲击磨硬质高岭土、滑石、石墨、方解石、石膏、硅藻土、硅灰石、重晶石、叶腊石、氢氧化铝粉碎

点我去除广告

分级式冲击磨

工作原理:

物料由进料装置输送至主机粉碎腔,物料与高速回转器件及颗粒之间互相冲击、碰撞、磨擦、剪切、挤压而实现粉碎。粉碎后的物料通过分级轮实现粗细粉的分离,粗粉流入粉碎腔再次粉磨,净化的气体由引风机排出。

设备特点:

1、低能耗:集离心粉碎、冲击粉碎、挤压粉碎于一身,比其它类机械粉碎机节能高达40~50%。

2、高细度:配备自分流式分级系统,产品细度≥2500目。

3、入料范围大:入料粒度≤50mm,物料仅需经一级粗破设备。

4、低磨损:粉碎部分易损件采用复合耐磨新材料,使用寿命长,加工莫氏硬度≤5的物料时无污染。

5、机械稳定性强:可长期24小时不停机生产。

6、功能全:

可粉碎针状物料,做到成品长径比15:1;

粉碎过程无温升,适合于热敏性材料的粉碎;

可对烧结团聚超细物料进行打散作业,粒度恢复率达100%;

具有颗粒整形功能,有效提高堆积密度。

可粉碎纤维组织的材料;

可粉碎水分含量高的物料,具有烘干功能;

可粉碎粘性强的物料。

7、负压生产,无粉尘污染,环境优良。

8、自动化程度高,稳定性强,操作简便。

9、整个系统采用自动化控制,可实现一键式启停,操作简单方便与中控联接可实现远程控制。

适用范围:

1、 非金属矿典型物料有: 硬质高岭土、滑石、石墨、方解石、石膏、硅藻土、硅灰石、重晶石、叶腊石、氢氧化铝等材料的超细粉碎和纳米碳酸钙、氧化铈等物料的超细粉碎、打散。

2、 热敏性典型物料有: 乳糖、蜡、树脂、脂肪、骨粉、植物等

3、 中草药与原料的超细加工典型物料有: 花粉、山楂、香菇、珍珠粉、胃药、尼莫地平、抗生素类药物、灵芝、五倍子、何首乌、穿心莲、薄荷、鱼腥草、蕨根、葛根、板蓝根等。

主要技术参数main technical parameters

设备型号

model

入料粒度

max feed size

成品细度

product size

生产能力

capacity

装机功率

power

zj-c100

<3 mm

1-75?m

3-15kg/h

12 kw

zj-c200

<3 mm

1-75?m

20-100 kg/h

25kw

zj-c400

<3 mm

1-75?m

60-400 kg/h

65kw

zj-c600

<3 mm

1-75?m

100-1000 kg/h

100kw

zj-c1000

<3 mm

1-75?m

400-2000 kg/h

160kw

zj-c1250

<3 mm

1-75?m

600-4000 kg/h

200kw

working principle:

the material is transported from the feed device to the main crushing chamber, and the materials are smashed, collided, rubbed, sheared and squeezed with the high speed rotating device and particles. after crushing, the material is separated by a grading wheel, and the coarse powder flows into the crushing cavity and is pulverized again, and the purified gas is discharged by the draft fan.

equipment features:

1, low energy consumption: centrifugal grinding, impact grinding, crushing, crushing, grinding, energy saving than other mechanical shredders up to 40-50%.

2, high fineness: equipped with self flow type classification system, fineness≥2500 mesh.

3, feed range: max feed size≤50mm, only the material level coarse crushing equipment.

4, low wear: crushing parts wearing parts with complex wear resistant material, long service life, mohs hardness≤ 5 no pollution when material.

5, strong mechanical stability: can not be stopped for 24 hours.

6, full-featured:

it can crush needle shaped material and achieve the ratio of length to diameter of 15:1;

the grinding process of temperature rise, suitable for heat sensitive material crushing;

the sintering and agglomeration superfine materials can be dispersed and the recovery rate of particle size is 100%;

with particle shaping function, it can effectively improve the bulk density.

material that can crush fibrous tissue;

the utility model can grind materials with high moisture content, and has drying function;

material capable of crushing viscous material.

7, negative pressure production, no dust pollution, good environment.

8, high degree of automation, stability, easy to operate.

9, the whole system adopts automatic control, which can realize one button type start and stop. the operation is simple and convenient, and the central control connection can realize remote control.

scope of application:

1, non-metallic mineral materials are typical of hard kaolin, talc, graphite, calcite, gypsum and diatomite, wollastonite, barite, pyrophyllite, aluminum hydroxide materials such as ultra-fine grinding and nano calcium carbonate, cerium oxide materials such as ultra-fine grinding,.

2, the sensitive material of typical materials are: lactose, wax, resin, fat, bone, plants etc.

3, typical materials, fine processing of chinese herbal medicine and raw materials are: pollen, hawthorn, letinous edodes, pearl powder, stomach medicine, nimodipine, antibiotics, galla chinensis, ganoderma lucidum, polygonum multiflorum, andrographis, mint, houttuynia, fern root, radix puerariae, radix isatidis etc..

适用物料通用

进料粒度≤3mm

出料粒度0.075mm

原理高速万能粉碎机

展开

分级式冲击磨硬质高岭土、滑石、石墨、方解石、石膏、硅藻土、硅灰石、重晶石、叶腊石、氢氧化铝粉碎

点我去除广告

分级式冲击磨

工作原理:

物料由进料装置输送至主机粉碎腔,物料与高速回转器件及颗粒之间互相冲击、碰撞、磨擦、剪切、挤压而实现粉碎。粉碎后的物料通过分级轮实现粗细粉的分离,粗粉流入粉碎腔再次粉磨,净化的气体由引风机排出。

设备特点:

1、低能耗:集离心粉碎、冲击粉碎、挤压粉碎于一身,比其它类机械粉碎机节能高达40~50%。

2、高细度:配备自分流式分级系统,产品细度≥2500目。

3、入料范围大:入料粒度≤50mm,物料仅需经一级粗破设备。

4、低磨损:粉碎部分易损件采用复合耐磨新材料,使用寿命长,加工莫氏硬度≤5的物料时无污染。

5、机械稳定性强:可长期24小时不停机生产。

6、功能全:

可粉碎针状物料,做到成品长径比15:1;

粉碎过程无温升,适合于热敏性材料的粉碎;

可对烧结团聚超细物料进行打散作业,粒度恢复率达100%;

具有颗粒整形功能,有效提高堆积密度。

可粉碎纤维组织的材料;

可粉碎水分含量高的物料,具有烘干功能;

可粉碎粘性强的物料。

7、负压生产,无粉尘污染,环境优良。

8、自动化程度高,稳定性强,操作简便。

9、整个系统采用自动化控制,可实现一键式启停,操作简单方便与中控联接可实现远程控制。

适用范围:

1、 非金属矿典型物料有: 硬质高岭土、滑石、石墨、方解石、石膏、硅藻土、硅灰石、重晶石、叶腊石、氢氧化铝等材料的超细粉碎和纳米碳酸钙、氧化铈等物料的超细粉碎、打散。

2、 热敏性典型物料有: 乳糖、蜡、树脂、脂肪、骨粉、植物等

3、 中草药与原料的超细加工典型物料有: 花粉、山楂、香菇、珍珠粉、胃药、尼莫地平、抗生素类药物、灵芝、五倍子、何首乌、穿心莲、薄荷、鱼腥草、蕨根、葛根、板蓝根等。

主要技术参数main technical parameters

设备型号

model

入料粒度

max feed size

成品细度

product size

生产能力

capacity

装机功率

power

zj-c100

<3 mm

1-75?m

3-15kg/h

12 kw

zj-c200

<3 mm

1-75?m

20-100 kg/h

25kw

zj-c400

<3 mm

1-75?m

60-400 kg/h

65kw

zj-c600

<3 mm

1-75?m

100-1000 kg/h

100kw

zj-c1000

<3 mm

1-75?m

400-2000 kg/h

160kw

zj-c1250

<3 mm

1-75?m

600-4000 kg/h

200kw

working principle:

the material is transported from the feed device to the main crushing chamber, and the materials are smashed, collided, rubbed, sheared and squeezed with the high speed rotating device and particles. after crushing, the material is separated by a grading wheel, and the coarse powder flows into the crushing cavity and is pulverized again, and the purified gas is discharged by the draft fan.

equipment features:

1, low energy consumption: centrifugal grinding, impact grinding, crushing, crushing, grinding, energy saving than other mechanical shredders up to 40-50%.

2, high fineness: equipped with self flow type classification system, fineness≥2500 mesh.

3, feed range: max feed size≤50mm, only the material level coarse crushing equipment.

4, low wear: crushing parts wearing parts with complex wear resistant material, long service life, mohs hardness≤ 5 no pollution when material.

5, strong mechanical stability: can not be stopped for 24 hours.

6, full-featured:

it can crush needle shaped material and achieve the ratio of length to diameter of 15:1;

the grinding process of temperature rise, suitable for heat sensitive material crushing;

the sintering and agglomeration superfine materials can be dispersed and the recovery rate of particle size is 100%;

with particle shaping function, it can effectively improve the bulk density.

material that can crush fibrous tissue;

the utility model can grind materials with high moisture content, and has drying function;

material capable of crushing viscous material.

7, negative pressure production, no dust pollution, good environment.

8, high degree of automation, stability, easy to operate.

9, the whole system adopts automatic control, which can realize one button type start and stop. the operation is simple and convenient, and the central control connection can realize remote control.

scope of application:

1, non-metallic mineral materials are typical of hard kaolin, talc, graphite, calcite, gypsum and diatomite, wollastonite, barite, pyrophyllite, aluminum hydroxide materials such as ultra-fine grinding and nano calcium carbonate, cerium oxide materials such as ultra-fine grinding,.

2, the sensitive material of typical materials are: lactose, wax, resin, fat, bone, plants etc.

3, typical materials, fine processing of chinese herbal medicine and raw materials are: pollen, hawthorn, letinous edodes, pearl powder, stomach medicine, nimodipine, antibiotics, galla chinensis, ganoderma lucidum, polygonum multiflorum, andrographis, mint, houttuynia, fern root, radix puerariae, radix isatidis etc..

在线询盘/留言