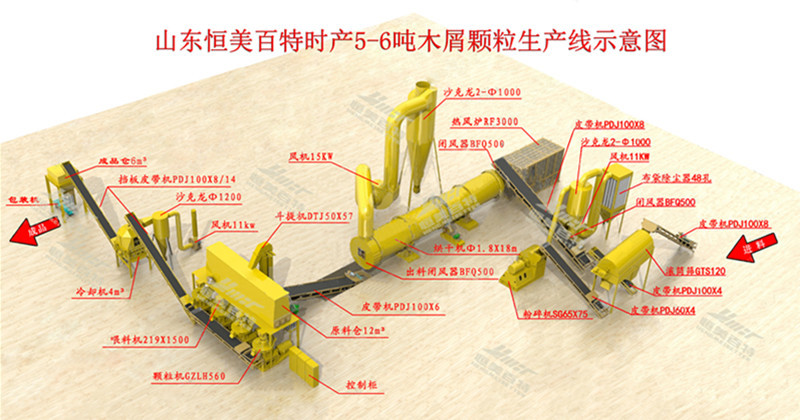

山东恒美百特时产4-6吨木屑颗粒生产线,3D动画演示视频。

颗粒生产阶段

Stages of pellet making

一般情况下,需要用一条完整的生产线来生产颗粒。颗粒生产的技术包括以下步骤:削片、粉碎、筛分、烘干、制粒、冷却和包装。

As a rule, a complete pellet line is used in order to produce pellets. The technology of pellet making consists of following steps: crushing, screening, drying, pelletizing, cooling and packing.

因此,需要各种不同的设备来完成这些步骤。这些设备包括剥皮机或削片机、锤式粉碎机、烘干机、颗粒机(压块机)、冷却和包装机。

So, different kinds of equipment are required to accomplish them. This equipment includes debarker or chipper, hammer mill, dryer, pellet mill (press), cooling and packing machines.

制粒设备

Units of pelleting equipment

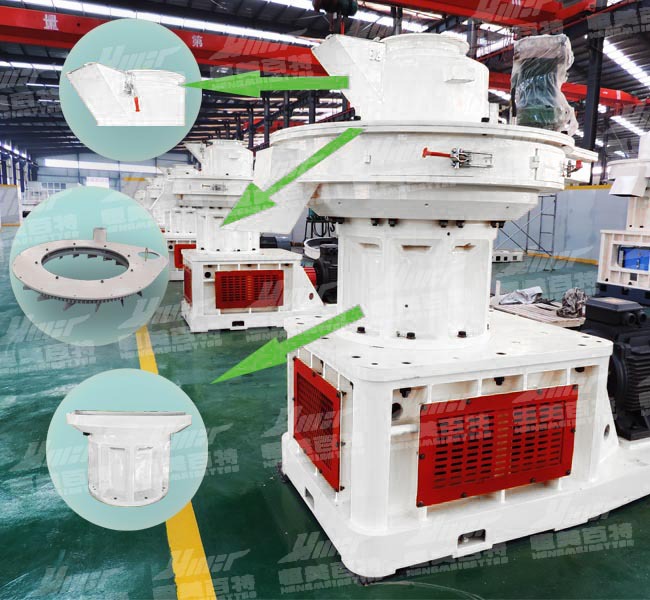

立式环模颗粒机

立式环模颗粒机特点:

1、垂直进料,不易堵塞;

2、模具立式静止安装;双层上下两用,降本增效;

3、压轮高速旋转,产生离心力,使物料分布均匀;

4、两套润滑系统,保证设备运转部件润滑充分;

5、降温除尘,达到制粒室的温度恒温效果,减少部件高温油脂溢出或积碳结块,破坏润滑系统的运行

1, vertical feed, not easy jam;

2, mold the vertical static installation; Double up and down dual-use, authors efficiency;

3, pressure wheel at high speed, centrifugal force, uniform distribution of material;

4, two sets of lubrication system, ensure the equipment running parts lubrication fully;

5, cooling dust to granulating chamber temperature constant temperature effect, reduce overflow or carbon parts of high temperature grease agglomerate, damage the operation of the lubrication system

木片机

1.机器由基座、刀辊、上下喂料机构、送料装置和液压缓冲系统及电气控制系统所组成。进料装置分皮带输送机或振动给料机两种;皮带机由下喂料辊电机带动。

2.上喂料辊转动方向与刀辊相同,下喂料辊转动方向与刀辊相反。滚齿错开,能够使碎屑得到清理。

3.刀辊是木片机的工作部件,由钢板焊接而成。具有较好的刚性和惯性矩,并经过动平衡检测。

4.切削过程是由飞刀和底刀来完成的,飞刀和底刀的间距要保持在0.5-1mm。

5. 切削后的木片尺寸为30mm左右

6.适用于大直径的木头,树枝,木板等

1. The machine consists of base, knife roller, the feeding mechanism, feeding device and the liquid

Pressure buffer system and electric control system. Feeding device belt conveyor or vibrating feeder two; Belt conveyor by the feed roller motor drive

2. The feed roller rotation direction is the same as the knife roller, the feeding roller in contrast to the knife roller rotation. Hob stagger, can make debris is cleared.

3. The knife roller is wood machine's working parts, by the steel plate welded together. Has good rigidity and moment of inertia, and through dynamic balance test.

4. The cutting process is accomplished by the fly cutter and bottom knife, fly cutter and bottom knife spacing must keep in 0.5 1 mm.

5. After cutting the wood size is around 30 mm

6. Suitable for large diameter logs, branches, wood, etc

多功能粉碎机

1.结构合理,转子经过动平衡检测,运行平稳;

2.机器外壳增加加强筋,保证机器工作时的稳定性;

3.进料口上方焊有螺纹钢,提高生产效率。它的作用:a. 增大碰撞率,提高效率;b.保护筛片;

4.适用范围广,进料口可根据物料的尺寸来选择朝上或朝一侧,因此可以粉碎一些长的细的物料,例如树枝,各类农作物秸秆等;

5.此机器可添加水冷却系统,在机器工作时同时对机器进行冷却,保证机器长期工作的稳定;此功能只应用于PVC板的粉碎

6.本系列粉碎机主要适用于能源颗粒行业

1. Reasonable structure, rotor dynamic balance test, smooth operation;

2. The machine shell increase stiffener, guarantee the stability of the machine to work;

3. The above feeding port has rebar welding, improve production efficiency. Increase its role: a. collision rate, improve the efficiency; B. protection screen pieces;

4. The applicability is wide and inlet can choose according to the size of the material up or toward the side, so you can crush some long thin material, such as branches, all kinds of crops straw, etc.;

5. This machine can add water cooling system, cooling for the machine when the machine is working, ensure the stability of the machine work for a long time; This function only applies to the shattering of the PVC board

6. This series of crusher is mainly used in the industries of energy particles

烘干机

因为新鲜原木含有丰富的水分,所以加工前应对它们进行干燥。同时,水分太容易蒸发,这使处理的材料缩水、发霉或出现其他问题。因此,用这种材料制成的颗粒质量不好。这就是为什么需要烘干机为进一步造粒准备材料。通常,适当的水分含量应为12-17%。

As fresh wood logs contain significant amount of moisture, they should be dried before processing. At the same time, moister evaporates too easily, which makes handled material shrunk, mildewed or spoiled in any other way. Consequently, pellets, made of such material, are of low quality. That is why drying machine is required to prepare material for the further stages of pelletizing process. As a rule, an appropriate moisture content should equate 12-17 per cent.

有两种类型的烘干机:滚筒式木屑烘干机和导管式木屑烘干机。第一种是普通类型,被广泛应用于颗粒厂。它的容量从2.5-36吨不等。同时,导管式木屑烘干机的容量不是那么高;然而,这种类型的烘干机的优点是低能耗和低成本。

There two types of dryers: rotary sawdust (drum) drying machine and pipe sawdust dryer. The first one is a common type and is widely used in pellet plants. Its capacity varies from 2.5 to 36 tonnes. At the same time, the capacity of pipe sawdust dryer is not so high; however, the advantages of this type of dryer are low energy consumption and low cost.

颗粒机

应用于颗粒生产的主要阶段。用先前处理好的原料制成颗粒。颗粒机操作的原理是与粉碎机相反。粉碎机用来粉碎原木,而颗粒机被应用于生产更大、均匀的团块。

Pellet mills, also known as pellet presses are applied at the main stage of pellet production. They are used to create pellets of previously processed raw material. The principle of pellet mill operation is opposite to hammer mill one. While hammer mill is used to pulp wood logs, pellet mill is applied to create larger, homogeneous mass.

有各式各样的颗粒机,可分为两大类:大型和小型颗粒机。与此同时,大型颗粒机主要有两种,包括平模和环模。一般情况下,立式环模颗粒机是最适合做生物质燃料的颗粒机。

Has all kinds of pellet machine, can be divided into two broad categories: large and small particles machine. At the same time, there are two main types of large particles machine, including flat die and die. In general, vertical ring die pellet machine is the most suitable for biomass fuel pellet machine.

冷却机

在颗粒生产的最后阶段,要运用到冷却机。使用这种机器能够使颗粒温度从80-90℃降到室内温度。它还能使水分含量从17%-18%降到12%-13%。

In the final phase of grain production, and cooling machine to use. Using this machine can make particle temperature from 80-90 ℃ to room temperature. It also can make the moisture content from 17% to 17% to 12% - 13%.

1、SKLN系列逆流式冷却器是我单位开发研制成功的新一代冷却设备,

主要用于制粒后高温颗粒的冷却。

2、该机具有独特的冷却机理,冷却风与颗粒物料逆向运动,使物料由下

而上逐渐得到冷却,避免了一般立式冷却器因聚冷所造成的颗粒表面开

裂,心部水分和热量在冷却时间内难以散发以及易碎等缺点。

3、该机采用振动锁紧装置,提高了冷却效果、降低了颗粒破碎率、根

除了颗粒变硬后冷却器无法工作的弊病,同时降低了功耗。冷却效果优

于国内现有产品,并超过国家标准。冷却后的料温不高于室温+5℃,降水

率不低于3.8%,对生产高质量的颗粒饲料,延长颗粒储存时间,提高经济效

益起到了卓越的作用。

4、该机产量大,冷却效果好,自动化程度高,噪音低,维修少,国外先进国

家广泛采用该机型,是高级取代型冷却设备。

1, SKLN series counterflow cooler is my unit development and successfully developed a new generation of cooling equipment,

It is mainly used for granulating high-temperature particles after cooling.

2, this machine has a unique mechanism of cooling, cooling air and particle material reverse motion, make the material from below

And gradually cool, avoid the general vertical cooler caused by poly cold surface of the particles

Crack, the heart of moisture and heat in the cooling time is difficult to send out and brittle faults.

3, the machine USES vibration locking device, improve the cooling effect, reduces the particle breaking rate, root

In addition to the disadvantages of particles harden after cooler will not work at the same time reduces the power consumption. Optimal cooling effect

In the domestic existing products, and more than the national standard. After cooling the material temperature is not higher than room temperature + 5 ℃, precipitation

Rate of not less than 3.8%, the production high quality pellet feed, to extend the time of grain storage, improve the economic efficiency

Yi has played a prominent role.

4, the machine production is large, cooling effect is good, high degree of automation, low noise, less maintenance, advanced foreign countries

Widely used in the model, replace type cooling equipment is advanced.

山东恒美百特(http://www.keliji1688.com)主营:木屑颗粒机;秸秆颗粒机;生物质颗粒机;燃烧机;木片机;粉碎机;烘干机;冷却机;饲料机械;有机肥机械;移动式建筑垃圾破碎站。欢迎各界朋友来厂参观考察。恒美百特,品质致胜。

关注山东恒美百特,获取更多生物质颗粒行业最新信息。

![]()

![]()